High strength fasteners for a variety of industries

Dunham Products has built its reputation on strength, and supplies fasteners to industries that have incredibly high standards for quality, safety and strength.

Since we serve a wide variety of industries, we are ISO 9001:2015 certified with a robust and effective quality program, and perform every project with the highest levels of quality.

You can feel confident as a partner, because Dunham Products provides:

- A wide range of delivery options that can meet almost any schedule or deadline

- Customer communication and service that is second to none

- Production or modification of parts in virtually any type of material, including tightly controlled and standardized materials such as food or medical grade, etc.

- Utilization of any drawing or spec sheet

- Defense Federal Acquisition Regulation Supplement (DFARS) compliant

- Restriction of Hazardous Substances Directive (RoHS) compliant material

With Dunham Products, quality is key. Our Quality Policy Statement: “Produce a quality product through customer communication and employee involvement.”

We don’t just say it. We mean it. We practice it. We live it.

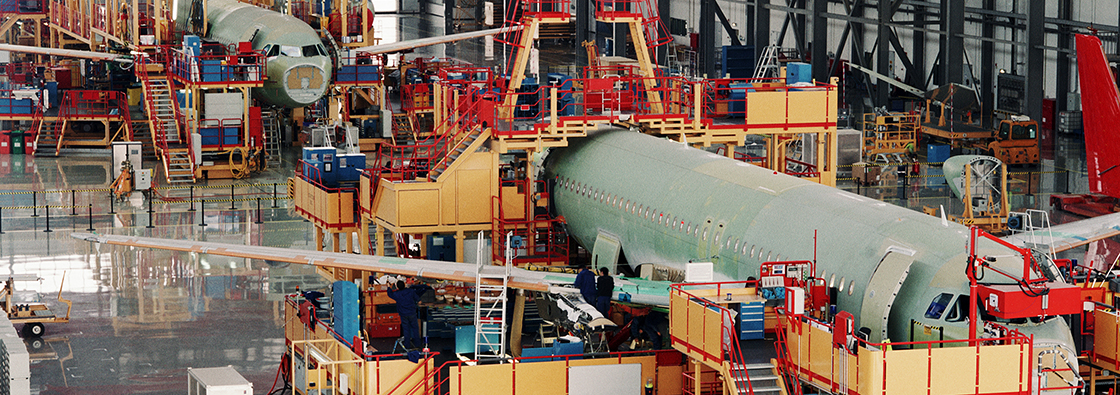

Aircraft

Our aircraft fasteners can be found from nose to tail and wingtip to wingtip. Studs are available in both unified and metric sizes in virtually any diameter and length. DFARS and RoHS compliant.

Military

Our fasteners for the military and defense industry meet or exceed all quality standards and procurement requirements and are DFARS and RoHS compliant.

Agricultural

Agricultural machinery works hard. In fact, it takes a beating. We provide high-strength, vibration-resistant fasteners typically found in the chassis, seats, and access panels. Our fasteners feature high shear and tensile strength.

Natural Gas & Oil

Fasteners that have extremely high shear and tensile strength and are proven to remain stable in high-vibration environments, such as trucks and trailers, railcars, and downhole drilling applications.

Nuclear

Fasteners created especially for the nuclear industry, which requires high strength and that can withstand high temperatures and environmental variances. DFARS and RoHS compliant.

Wind Power

Small things keep big things from failing. Power generated from wind depends on high strength fasteners from the ground-based structure, to the blades, to the generator. And small, relatively inexpensive fasteners are integral to keeping big things operating.

Marine

High-strength fasteners in marine applications need to be able to withstand extreme environments and corrosion, in addition to “normal” stress, vibration and fatigue.

Racing Hardware

Racing creates a great deal of torque stresses and vibrations. In these conditions, the weakest component will fail first, and many races have been lost because fasteners have failed.

Medical Components

Stainless steel and titanium high strength fasteners used in the medical industry need to be high-performance, corrosion-resistant, and light weight. We can provide fasteners according to our customers’ requirements. DFARS and RoHS compliant.

Dunham Products would love to hear about your next project! If you have a project or challenge, we’ll help you get it done!